Overview

Working in any area of supply chain management has never been simple. And because so many enterprises have massively expanded their operations in recent years into new markets, verticals, or both, some of their chains look more like labyrinths.

All the while, each area of the supply chain generates massive amounts of data. Supply chain analytics allows organizations to make sense of all that data and put it to good use.

What is supply chain analytics?

Supply chain analytics is the collection, processing, and analysis of data sourced from key points along the chain.

Common sources of data used for supply chain analysis include:

- Applications and systems used for procurement, inventory management, product design and manufacturing, order processing and fulfillment, warehouse management, and logistics

- Customer data from sales and marketing tools, such as enterprise resource planning (ERP) and customer relationship management (CRM) solutions

- Data from third-party suppliers and other partners

Increasingly, supply chain analytics solutions are incorporating some of today's most talked-about data trends—namely, cutting-edge processes and technologies. Examples include stream processing for real-time data analytics, "digital twin" models of supply chains, and machine learning-based natural language processing for sources of unstructured text data in documents.

The journey to supply chain visibility

Ultimately, the goal of supply chain analytics is to shine a light on every single phase of the chain—i.e., to achieve true supply chain visibility. Reaching this level of visibility requires these essential steps:

- Assessing the performance and efficiency of workers, equipment, technology, processes, vehicles, routes, and various other elements of the logistics life cycle through the lens of advanced analytics is critical for identifying strengths and weaknesses.

- This analysis also helps enterprises make their supply chain leaner and more efficient.

- With predictive analytics, supply chain teams can reasonably predict the trajectory of demand and adjust accordingly, and also look at the potential effects of larger macroeconomic factors, like the possibility of recession or inflation.

Supply chain analytics solutions by industry

Industries with particularly complicated supply chains have the most to gain from supply chain analytics. Consider the following examples:

Automotive: Supply chain analytics allows automakers to comprehensively assess key performance indicators (KPIs) of output, efficiency, and effectiveness throughout all phases of the supply chain. This is critical in a highly competitive and tightly regulated industry.

Predictive analytics helps auto manufacturers identify potential bottlenecks in procurement, production, or shipping. Companies in this sector can also put themselves ahead of the curve by analyzing web interactions and customer data to discover emerging taste trends—for specific features, color schemes, designs, and so on—and forecast demand with greater accuracy.

Food and beverage: Supply chain analytics helps food and beverage companies solve numerous challenges. Real-time visibility into inventory management means there's less chance of overstocking or under-procuring. Analytics also improves product traceability, making it easier to maintain as orders are processed, packaged, shipped, and delivered, ensuring better food safety and quality. This is especially important in an era where many people are more interested than ever in knowing exactly where their food comes from and what's in it.

Retail and e-commerce: Brick-and-mortar and e-commerce retailers use analytics to track numerous KPIs, including total supply chain management cost of percentage sales, fill rate, and cash-to-cash cycle time. When retail supply chain managers have complete visibility into these and other metrics, they can determine if supply chain costs are worth the revenue they're bringing in and adjust accordingly if needed.

Supply chain analytics contributes significantly to process improvements that directly affect customer satisfaction. One major example is calculating the perfect order rate—the number of orders fulfilled on time and with no errors or damage to goods. Retailers also use analytics to track carrier allocations. This lets them know when to switch a batch of goods to a new shipping carrier to prevent disruption and ensure orders are delivered on time.

3 supply chain analytics examples

The following Teradata customers all used the techniques and tools of supply chain analytics to boost visibility and improve overall supply chain performance.

1. Unilever

When Unilever sought to turn itself into a more sustainable enterprise, the global consumer goods corporation knew it would need an analytics-based strategy. After migrating its key data infrastructure from on-premises to the cloud, Unilever adopted a cloud-ready data analytics platform to process, analyze, and report on critical data from multiple business lines—including its worldwide supply chain.

By examining marketing and sales data alongside manufacturing, logistics, and order fulfillment KPIs, Unilever discovered trends indicating a growing consumer interest in sustainability. This galvanized the company not only to expand its catalog to include organic and plant-based products, but also to tackle waste throughout the supply chain. This includes reducing plastics use as well as finding ways to create closed-loop supply chains (CLSCs) that recycle everything from packaging to—when possible—biological and food waste.

2. Norfolk Southern Corporation

Supply chain analytics is especially important to Norfolk Southern Corporation (NSC) because the rail carrier is a major part of many industries' supply chains. Suppliers of raw materials ranging from cotton and silk to steel, coal, and lumber rely on NSC freight trains to deliver materials to numerous container ports across 22 states in the eastern U.S.

Before adopting a versatile supply chain analytics solution, NSC was stuck with outdated legacy systems that couldn't make effective use of its supply chain data. Since then, the rail carrier has consistently used big data and analytics to optimize routes for greater efficiency, prepare for fuel and power requirements, create accurate crew schedules, monitor costs, and ensure timely deliveries.

3. Global automakers

Automotive manufacturers need comprehensive, end-to-end insights into their supply chains at all times to ensure steady production. Using supply chain analytics allows automakers to monitor part deliveries and costs from suppliers, project likely results of key logistics decisions—e.g., cost changes when working with a new shipping company—and maintain tight production schedules.

Auto companies analyze data from packaging plants, logistics services, original equipment manufacturers (OEMs), in-house manufacturing facilities, and other sources. This helps them gauge whether unexpected events, like container delays, will be severe problems and determine how to address them.

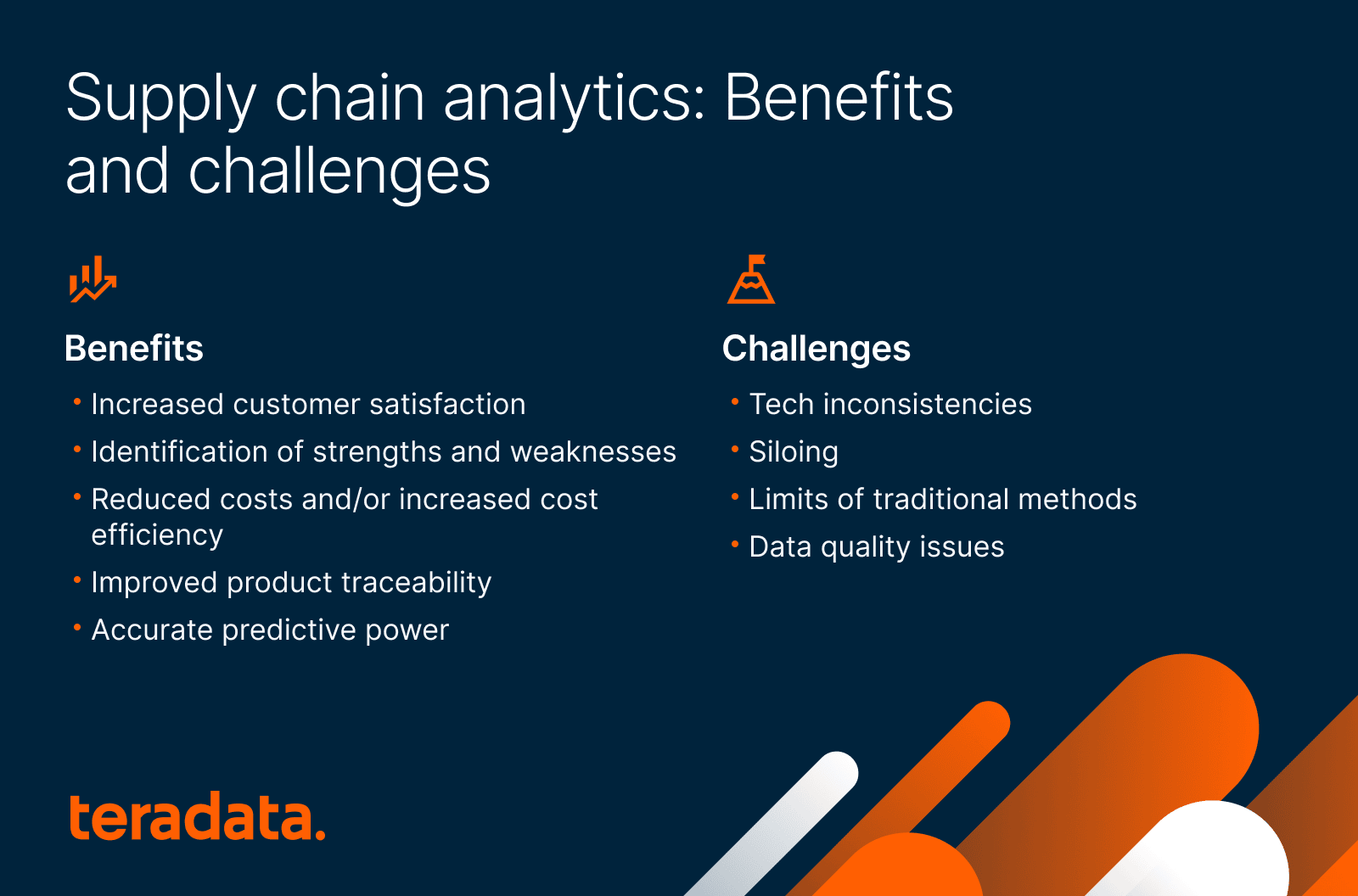

Benefits and challenges of supply chain analytics

Enterprises adopting high-level analytics for their supply chains will realize major benefits in numerous areas.

5 key supply chain analytics benefits

1. Increase customer satisfaction

This is arguably the most important benefit supply chain analytics can deliver.

When businesses know what products customers are ordering and what they're likely to order in the future—and any patterns within these spending habits—they know when to adjust the production of different goods. It also helps companies more effectively allocate personnel, spending, and resources. This means customers are more likely to get what they want when they want it. Furthermore, supply chain analytics also helps organizations determine customers' preferred purchase and delivery channels—in-store shopping, curbside pickup, or at-home delivery—and make sure those methods are always available.

2. Identify strengths and weaknesses

No supply chain is perfect. One enterprise may excel at planning efficient routes for on-time delivery but not be able to show off these strengths of late due to parts shortages. Another may be the exact opposite.

Supply chain analytics allows companies to precisely identify their pros and cons with granular data—and, more importantly, develop strategies for improving weaknesses and maintaining strengths.

3. Reduce costs and/or increase cost efficiency

By using big data in an organized manner throughout the supply chain, enterprises have greater visibility into costs ranging from parts orders to warehouse management expenses. Companies can find any costs that are superfluous or excessive, and adjust accordingly.

4. Improve product traceability

Every company wants to keep a close eye on its products throughout the supply chain. Doing so helps limit product damage or loss while in transit and better ensures accurate delivery.

But product traceability facilitated by analytics is also useful for enterprises looking to improve their sustainability and corporate responsibility initiatives. Traceability allows companies to gauge the environmental impact of products and measure any other harm—or benefit—they may cause.

5. Enable accurate predictive power

Using predictive analytics processes and solutions to get answers from supply chain data provides enterprises the opportunity to reasonably forecast the ebb and flow of supply and demand and then plan with these possibilities in mind. Predictive analytics also contributes to improved risk management by allowing analysts to examine data for risk indicators in real time, ranging from declining equipment performance to longer delivery times.

Potential supply chain data analytics challenges

Tech inconsistencies: Each unit of the supply chain operates differently than its counterparts. For example, an organization's manufacturing facilities might have intricate Internet of Things (IoT) deployments, while the warehouse team uses legacy systems. The latter might be unable to perform analytics at scale.

Data teams may need to provide training and/or sell legacy tech users on the merits of analytics. Expert oversight will remain crucial after the implementation of modern analytics as well.

Siloing: Any business units running on legacy systems are also quite likely to keep their information in a data silo. Siloing impedes analytics' capabilities and limits insights.

Limits of traditional methods: Early supply chain analytics processes and tools often focused too strongly on diagnostic or descriptive analytics-based interpretation of historical data. Modern enterprises need analytics solutions with real predictive and prescriptive analytics capabilities.

Data quality issues: All of the challenges above pose a risk to data quality. Inaccurate, incomplete, or otherwise quality-compromised data leads to inaccurate and incomplete reporting. Data analysts must implement appropriate data exploration, processing, and cleansing measures to ensure supply chain teams derive as much value from data as possible.

Supply chain analytics best practices

Enterprises must follow key best practices to maximize their supply chain data.

Integrate data across the tech stack

Data integration is essential for all analytics uses. Supply chain management professionals and data teams must work together to aggregate all relevant data sources, including websites, social channels, ERP, CRM, and inventory management software. Applications used in retail stores, warehouses, manufacturing plants, and fulfillment centers are also important.

Optimize inventory levels

Thorough demand planning via predictive analytics helps organizations take better control of inventory. For example, predictive analysis makes it possible to set minimum inventory levels that, when reached, trigger automatic reorders and minimize the impact of shortages.

Focus on critical areas

Every aspect of the supply chain matters, but analytics should be most closely focused on priority areas. While these vary by organization, demand planning, inventory placement, operational efficiency, and order fulfillment are common priorities.

Embrace data visualization

Using dynamic visualizations for reports based on supply chain analytics helps key metrics stand out to team members, especially those who aren't well-versed in analytics.

Adopt the right data analytics platform

Teradata Vantage, the connected data analytics platform for a hybrid multi-cloud world, is an ideal solution for optimizing supply chain analytics. With its robust data integration, data warehousing, and reporting capabilities, Vantage helps enterprises maintain data-driven supply chains with processes and products that move quickly, efficiently, and accurately.

To learn more, check out our blog on adding resiliency and flexibility to the supply chain through effective analytics implementation.

Supply chain analytics FAQs

What are the main types of supply chain analytics?

Supply chain analytics can be categorized into four main types:

-

Descriptive analytics: Understand what has happened in the supply chain. Examples include inventory levels over time, order fulfillment rates, and transportation costs.

- Diagnostic analytics: Understand why something happened. Examples include root-cause analysis of delivery delays, identifying bottlenecks in production, and analysis of supplier performance issues.

- Predictive analytics: Forecast what's likely to happen. Examples include demand forecasting, predicting stockouts or excess inventory, and risk assessment for supplier disruptions.

- Prescriptive analytics: Recommend actions to achieve desired outcomes. Examples include optimizing inventory levels, route optimization for logistics, and dynamic pricing strategies.

How should I get started with supply chain analytics for my organization?

Getting started with supply chain analytics involves a mix of strategic planning, data readiness, and tool adoption. Here's a step-by-step guide to help you launch effectively:

- Define your business goals: Start by identifying what you want to achieve with analytics. Do you want to reduce inventory costs, improve delivery time, or forecast demand more accurately? Clear goals will guide your data and tool choices.

- Assess your data readiness: Evaluate the quality and availability of your supply chain data. What systems are you using? Is your data clean, consistent, and accessible? Are key metrics being tracked? If not, consider a data cleansing and integration phase.

- Start with descriptive analytics: Build dashboards and reports to understand your current performance. Track key performance indicators (KPIs) like inventory turnover, fill rate, and on-time delivery. This helps establish a baseline and identify improvement areas.

- Move to diagnostic and predictive analytics: Once you understand what's happening, explore why and what's next. Use statistical tools or machine learning to analyze trends and patterns. Forecast demand, identify bottlenecks, or predict disruptions. Data scientists or analysts can help at this stage.

- Implement prescriptive analytics: Use optimization and simulation tools to make better decisions for inventory optimization, route planning, and supplier selection.

- Build a cross-functional team: Involve stakeholders from supply chain, information technology (IT) and data, finance, and operations. This ensures alignment and smooth implementation.

- Start small and scale fast: Begin with a pilot project, then expand based on results.